Crane has become the quintessential machinery in modern times in many sectors of the economy. Be it construction, shipping, automotive, manufacturing, a crane plays an important role that enhances both productivity and safety.

No two cranes are alike and with so many different types of cranes it is difficult to understand which crane is best fit for the application at your business. The most sought-after cranes providing economical and ergonomic lifting are gantry crane and jib crane.

Gantry Crane

A gantry crane is the Electric Overhead Traveling (EOT) crane. It has a bridge which is supported by two A-frame steel legs. Some gantry crane run on the embedded rail on the floor and some are equipped with casters so that the crane can be moved conveniently to different places. They are extensively used in rail yards, shipping yards, various manufacturing industries, warehouses.

Jib Crane

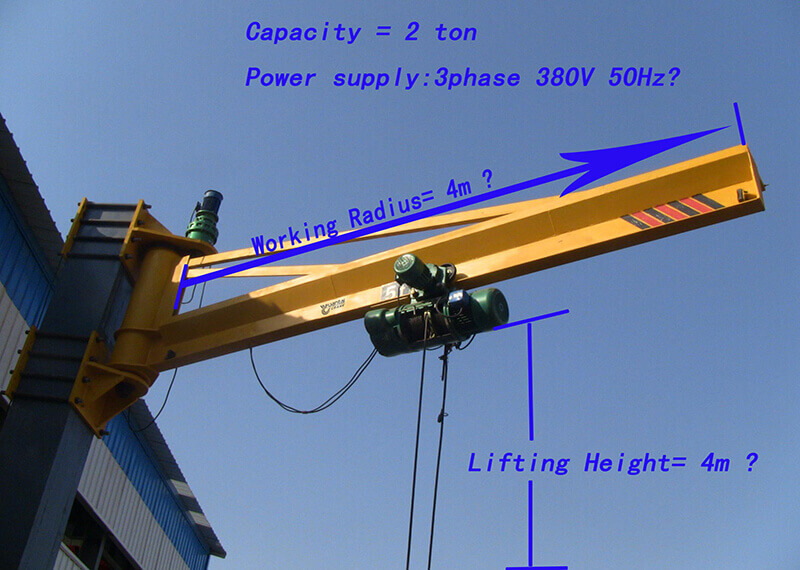

A jib crane is not a typical EOT. It is mounted on a single leg (which is usually fixed to ground or wall) It is efficient in specific lift application, especially in production application where load positioning and spotting are critical. It provides great value and practical lifting solutions and many diverse applications that require circular coverage in tight spaces, supplementing a large overhead crane system.

To make a better suited decision for the application of correct crane in your business, it is advisable to consult experts of a trusted crane manufacturer of Yuantai.

Gantry crane is an overhead crane that is used for heavy-duty applications. Gantry crane has vast applications and is used in a myriad of industries like equipment production and processing, power industry, cement casting, railway freight yard, shipping industry, hydropower stations, loading and unloading at port terminals, lifting heavy goods inside a factory, construction and installation sites etc.

Gantry crane reduces the labor greatly while improving the operating conditions of site workers, production capacity, and labor productivity of loading and unloading tasks. Gantry cranes ensure productivity, quality, and efficiency in a variety of fields and sites.

Crane is used for moving, lifting, raising, and lowering heavy objects. It has become the essential machinery in many industries, such as transportation, shipbuilding, aviation, automotive, and especially construction.

There are many types of cranes. However, the Electric Overhead Traveling (EOT) crane is the most popular one. It is suitable for daily weight lifting activities and requires less maintenance. EOT crane has many types from which we will discuss the difference between two cranes: jib crane and gantry crane.

The difference in design

The design is the first and foremost difference between the jib crane and the gantry crane. A gantry crane has two points of ends or supports with a horizontal I-beam in between the supports. These points of ends are usually on wheels so that the crane or the loads through the crane can be shifted to different locations. However, a jib crane has a single point of contact through which it is managed. It is usually fixed to the ground or wall. But it also comes as a portable crane.

The difference in movement

The gantry crane is used for moving weight in a straight line with the horizontal I-beam with the help of a chain house and trolley. The jib crane is also for lifting or moving weight. However, it must be portable to function the same as a gantry crane. If the jib crane is mounted in-ground, distance becomes a limitation.

The difference in usage

The gantry crane is used for a heavyweight that has to be moved to a distant location. They are mostly required in factories, power plants, seaports, and similar workspaces. Jib cranes are generally used for small weights to a shorter distance. They are suitable for tight workspaces. Additionally, jib cranes have the capacity to lift loads from the ground to higher locations like roofs. It can also be rotated from 180 to 360 degrees.

In a nutshell, the gantry crane and jib crane both are suitable for different purposes.

Factors to Consider While Buying Gantry Crane

While buying gantry cranes, you need to consider a myriad of technical factors. Let’s get down to some of the prime factors you need to keep in mind while choosing a crane for your site.

Lifting Capacity

When you are considering purchasing a gantry crane, make sure you choose the one with higher lifting capacity as it will save your manpower and time while improving the task efficiency. With higher lifting capacity, tasks can be handled without the need to indulge in multiple rounds of loading and unloading. While you are taking the lifting capacity into consideration, make sure you are also keeping the cost-effectiveness factor in mind to form a balance between time, quality, and cost.

Movability

See whether you need a movable crane for your unit to not. If you have to lift indoors as well as outdoor, then you might need a movable crane which in your case will be proven affordable and efficient.

Wheels

Your gantry crane should be mounted on wheels that should be able to balance and distribute the load. For sites where you need to lift infrequently, wheeled gantry cranes with adjustable lifting height are the most cost-effective solution.

Newer Models

While buying gantry cranes, make sure you are choosing an up-to-date and a newer model. New models can be pricey at times but if it matches your requirements, then you should consider choosing the latest models. If the old models are capable to suffice your requirements, then you shall choose the old models and bear some repairmen costs. This could make a huge difference in your budget while still sufficing your requirements.

For more information about jib crane or gantry crane or any other overhead cranes, feel free to get in touch with our team.

No Responses